X-ray and extreme ultraviolet optics

Researchers at Lawrence Livermore develop and deploy coating technologies to enable novel observations in the x-ray and extreme ultraviolet wavebands.

Developing multilayer coating technologies

Multilayer interference coatings are an enabling element of optical components for extreme ultraviolet (EUV) and x-ray observatories, providing capabilities for solar physics, planetary physics, and astrophysics. Multilayers consist of stacks of alternating thin film layers of two or more materials deposited on an optical substrate. The constructive interference between the layers results in high reflectance.

In the EUV and soft x-ray region (1–100 nanometers [nm]), multilayers can provide high reflectance at near-normal incidence, a regime where a single layer of any material would have zero reflectance. In the hard x-ray, multilayers are used to create high efficiency optics that operate at extremely shallow grazing incidence angles (hundredths of a degree) and require coating layers with sub-nanometer thicknesses, corresponding to just a few atoms of material.

Researchers at LLNL develop state-of-the-art multilayer coatings and implement them for space missions. Using capabilities including advanced metrology and in-band characterization techniques, materials science and modeling, and optical design, we can identify and study limitations of multilayer technologies and provide robust solutions for improving optics from the EUV to gamma-ray wavebands.

From left: Jennifer Alameda, Regina Soufli, Jeff Robinson, Marie-Anne Descalle, and Catherine Burcklen in front of the Mag-1 deposition system with its lid open. Four sputtering sources (materials) used in thin film depositions are inside the Mag-1. Two sources are 100 mm in diameter and the other two are rectangular, 127x250 mm2 in size.

X-ray and EUV optics development at LLNL falls into several overlapping areas:

Multilayer coating development to enable normal-incidence EUV and soft x-ray optics with compact geometries

Multilayer coating development to enable grazing-incidence hard x-ray and gamma-ray optics

Metrology and photometric calibration for research activities and flight optic quality assurance

Large-area coating capability to produce coatings with precise thickness control on curved optics for space telescopes

Leveraging state-of-the-art modeling capabilities, deposition facilities, and measurement facilities

Designing and fabricating multilayer coatings involve many challenges:

- Determining multilayer systems with high reflectance, appropriate spectral selectivity, and stable performance over time, for the specific wavelength region of operation.

- Addressing the sensitivity of materials to degradation mechanisms such as contamination, oxidation, and corrosion.

- Determining accurate refractive index values, including near absorption edges, which are essential for the reliable design of multilayer coating systems.

- Meeting stringent requirements for surface figure and surface roughness on optical substrates with various shapes and geometries (planar, curved, nested).

We address these challenges by studying the physics of periodic (narrowband) and aperiodic (broadband) multilayer coatings with nanoscale layers, including the crucial interfaces between layers, and by developing new multilayer material systems with improved properties. For hard x-ray applications, we improve performance by developing multilayer coatings with the thinnest achievable layers. We advance multilayer design algorithms, deposition methodologies, characterization methodologies, and corrosion barriers for extended lifetime stability.

Accurate substrate specification and metrology are an integral part of the development of these optical systems and represent one of the key competencies at LLNL. We implement state-of-the-art metrologies for measurements of surface figure and roughness of optical substrates for space applications.

Using these techniques, we have:

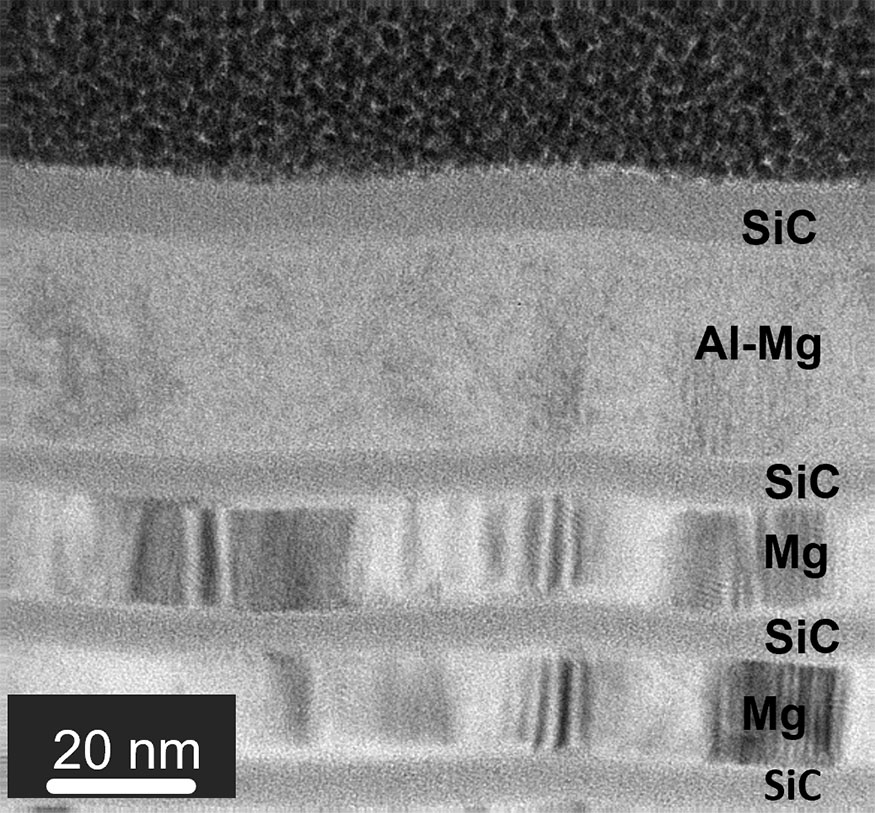

- Identified the corrosion mechanisms for magnesium-based multilayer coatings and developed corrosion barriers. These aluminum-based barriers address the issue of catastrophic corrosion, enabling magnesium multilayer use for space-borne instruments that require long-term stability.

- Developed new multilayer coatings for use in the EUV, including triple-wavelength magnesium-based multilayers and aluminum/scandium-based multilayers.

- Established accurate measurement methodologies for the refractive index of several important materials for EUV and x-ray optics: molybdenum, silicon, beryllium, iridium, yttrium, boron, strontium, silicon monoxide, boron carbide, platinum, chromium, and aluminum.

- Demonstrated narrowband multilayer optics that can operate at photon energies up to the soft gamma-ray spectral range. This is the highest photon energy where multilayers have been experimentally shown to work.

- Demonstrated efficient broadband multilayer coatings for photon energies from a few keV to more than 100 keV.

- Provided the multilayer coatings and calibration for the Atmospheric Imaging Assembly (AIA) instrument aboard NASA’s Solar Dynamics Observatory. We led the design, deposition, metrology, and photometric calibration of the four AIA telescopes, providing seven EUV narrowband channels ranging from 9.4 to 33.5 nm, each tuned to corresponding emission lines from the Sun’s ionized plasma.

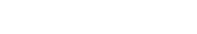

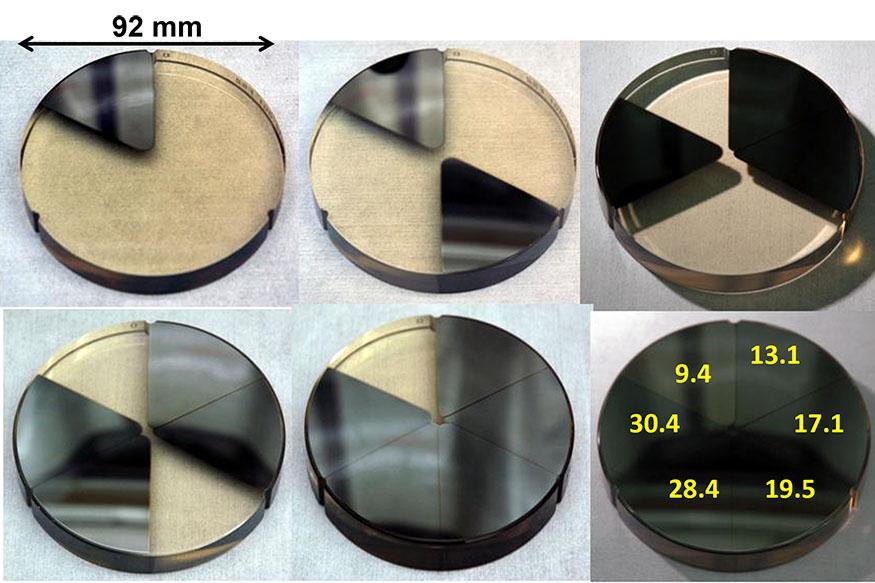

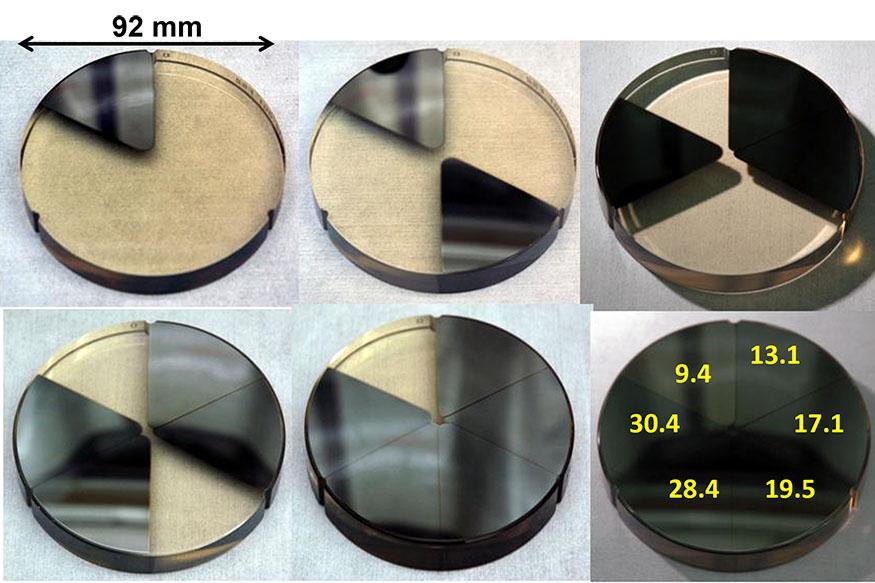

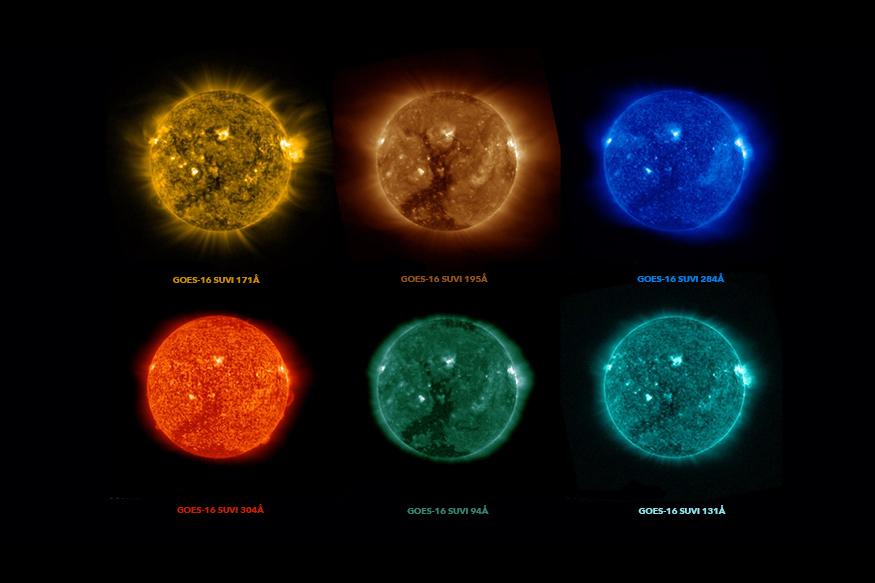

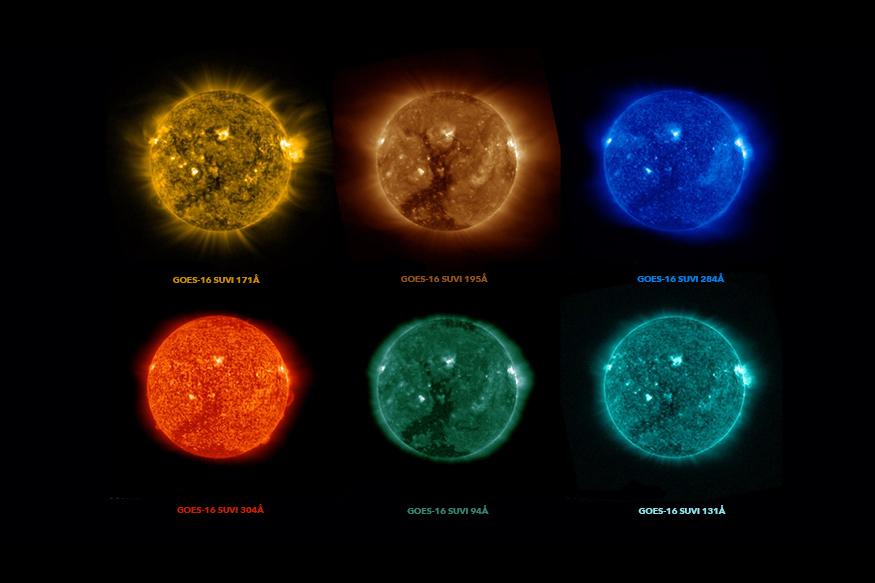

- Provided the multilayer coatings and calibration for the Solar Ultraviolet Imager (SUVI) telescopes aboard NASA/NOAA’s Geostationary Operational Environmental Satellites (GOES). Each mirror was coated in six spatial (60-degree) segments, providing six EUV narrowband channels on each mirror. We delivered twelve flight mirrors for six SUVI telescopes, launched in 2017 aboard GOES-16 and in 2018 aboard GOES-17. The remaining four telescopes are expected to launch in 2022 and into the late 2020s or early 2030s.

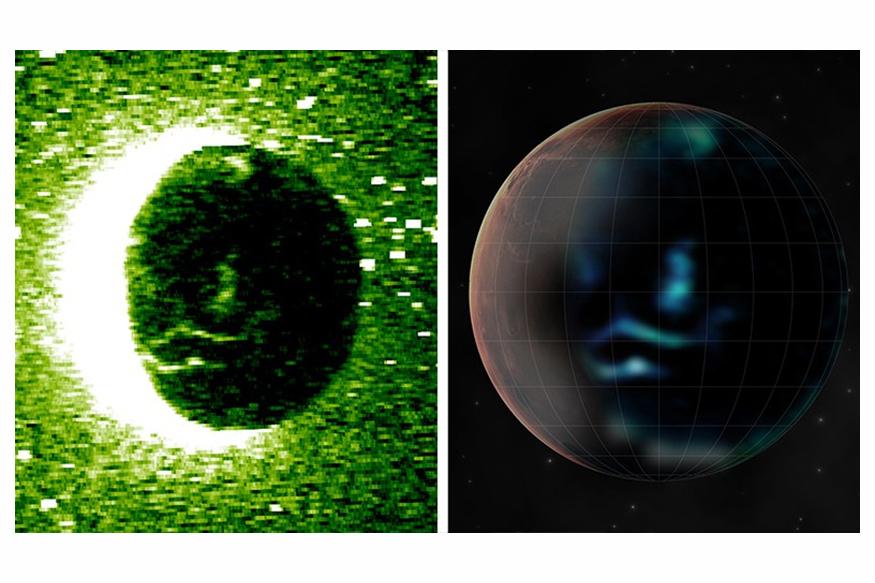

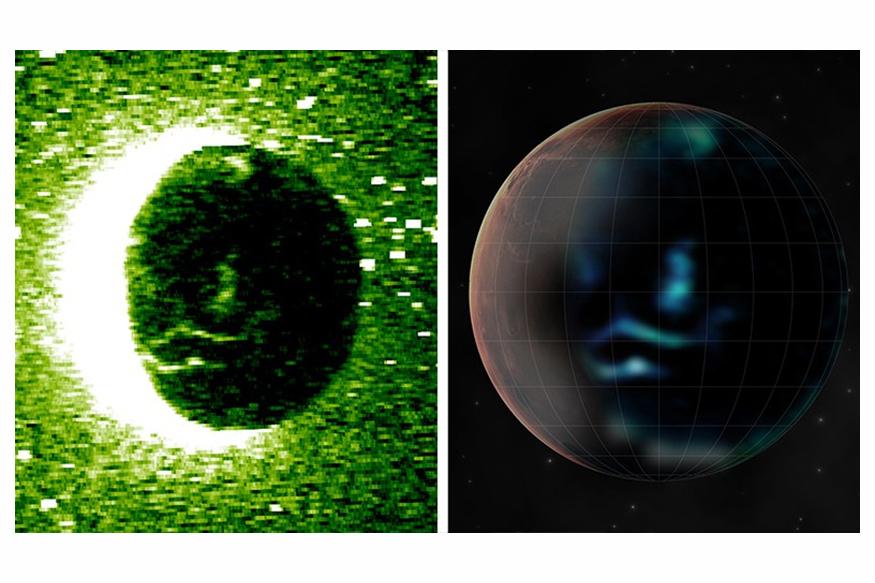

- Provided silicon-carbide coatings for the mirror and grating for the far-ultraviolet imaging spectrometer on the United Arab Emirates-led Hope Mars mission that launched in 2020. The Emirates Ultraviolet Spectrometer is studying the Martian atmosphere from 100–170 nm, and it has captured detailed images of auroras in the Martian sky. The silicon carbide coating allows imaging at shorter wavelengths than other Mars orbiting spectrometers, enabling observations of emission produced by the extended hydrogen exosphere at 102.6 nm.

- Developed beam splitters for astrophysics mission concepts. In a collaboration with the University of Iowa, we deposited multilayer coatings on a 2-micron-thick polyimide membrane to reflect 0.5 keV x-rays to a Bragg polarimeter and transmit 2–10 keV x-rays to the primary polarimeter for the Gravity and Extreme Magnetism Small Explorer Mission concept.

Techniques and tools serving a dual purpose

Optics developments that enable these studies of high-energy phenomena in space also enable diagnostic instrumentation for ground-based experiments. Advances in multilayer coating technologies and optics system design for space science applications have been key to enabling new capabilities such as the Wolter microscope developed for Sandia’s Z machine—the world’s strongest pulsed-power facility—and mirrors for K-shell fluorescence of plutonium and uranium.

Other applications enabled by multilayer optics include plasma diagnostics, radiation detection, attosecond physics, and EUV/x-ray laser sources. LLNL also pioneered and advanced EUV photolithography for semiconductor manufacturing, which was deployed to power the latest smartphones.

Image gallery

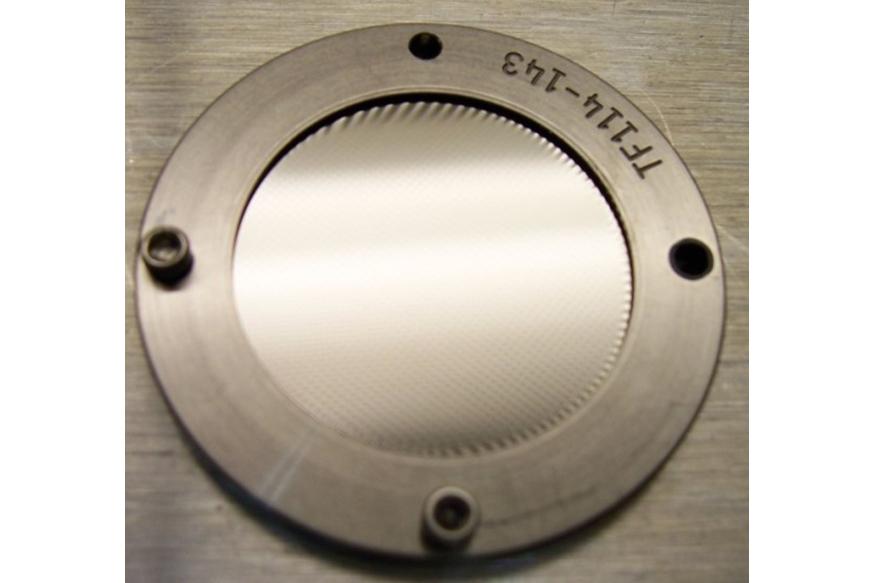

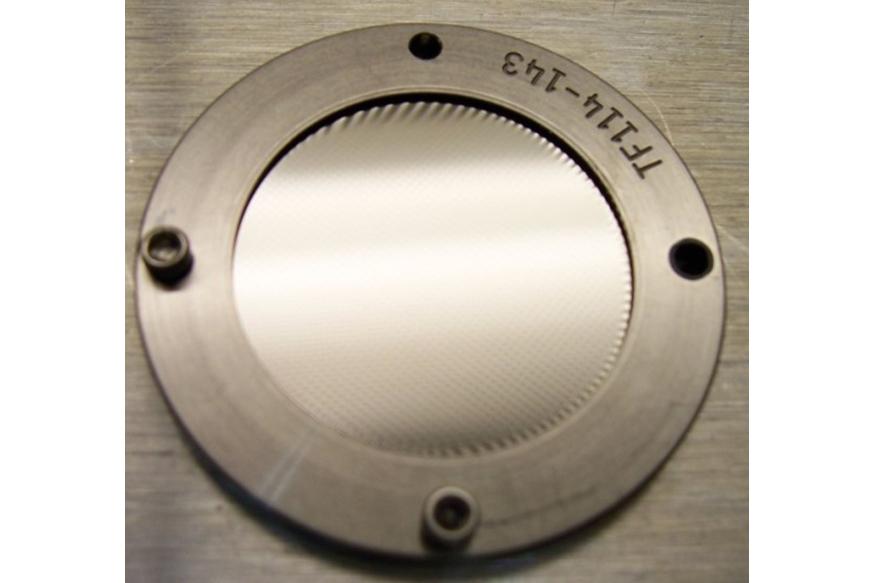

Different multilayer coating stages for the six segments of the Solar Ultraviolet Imager telescope’s secondary mirror. Numbers at the bottom right show the wavelength (in nanometers) corresponding to each segment.

An image taken by the Emirates Mars Ultraviolet Spectrometer and (right) an artist’s impression show discrete auroras on Mars’s night side. Image courtesy of Emirates Mars Mission.

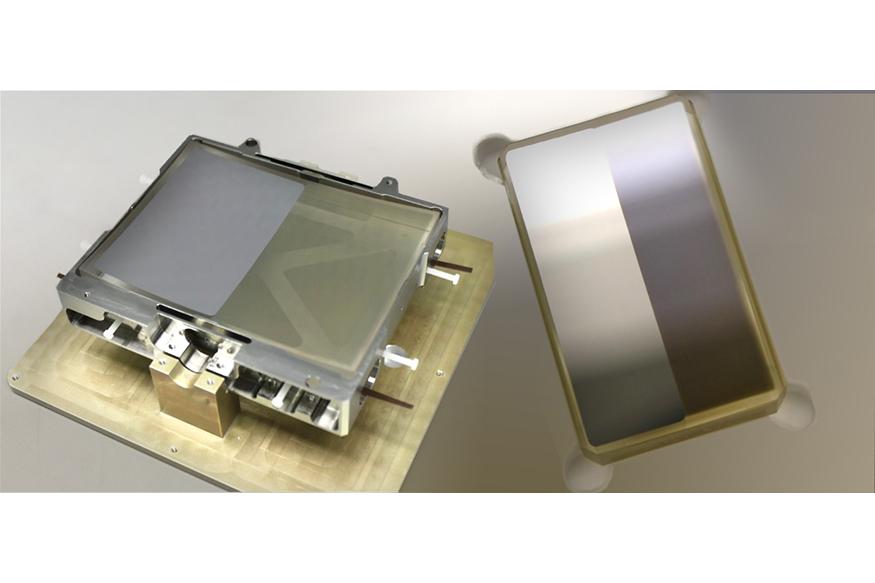

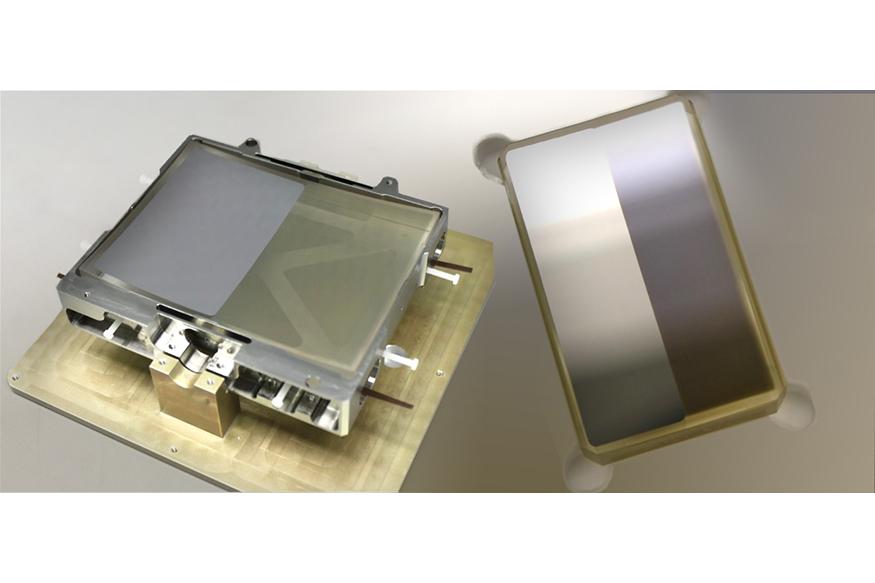

The Emirates Mars Ultraviolet Spectrometer (EMUS) toroidal diffraction grating with a silicon carbide coating developed by LLNL on the right half-area. (right) The EMUS spherical telescope mirror with a silicon carbide coating on the right half-area on top of a chromium underlayer developed by LLNL. Photo courtesy of Greg Holsclaw (LASP/University of Colorado).

These images of the Sun—captured by the six channels on the Solar Ultraviolet Imager instrument on board GOES-16—show a large coronal hole in the Sun’s southern hemisphere. Each channel observes the Sun at a different wavelength, allowing us to detect a wide range of solar phenomena. Our team co-developed and implemented the multilayer interference coatings that enabled this capability. Credit: NOAA

Coronal mass ejection from the Sun captured by NASA’s Solar Dynamics Observatory on August 31, 2012. The image is a composite of two wavelengths, 17.1 and 30.4 nanometers, and was captured by multilayer-coated telescope optics co-developed by LLNL. Credit: NASA/SDO.

Tungsten carbide/silicon carbide multilayer deposited by LLNL scientists on a polyimide membrane for the NASA Gravity and Extreme Magnetism Small Explorer Bragg Reflector Polarimeter. The optic’s diameter is 28.6 mm.

The Mag-1 magnetron sputtering deposition system with the lid open. Mag-1 is used for the deposition of single-layer as well as multilayer (periodic and aperiodic) thin film coatings.

Jennifer Alameda places a Silicon wafer substrate (used in test deposition runs) in the Mag-1 deposition system.

Underneath view of Mag-1 deposition system lid, showing the positions where substrates can be mounted.

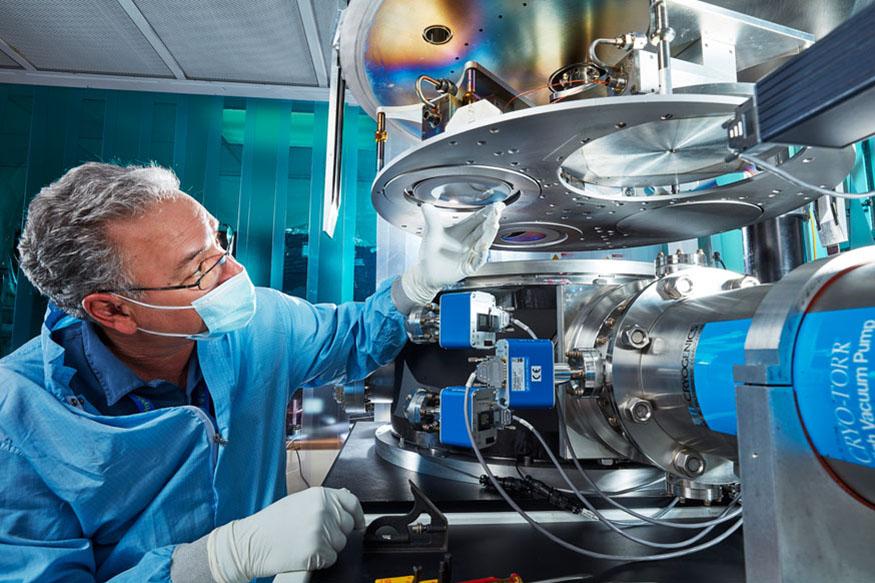

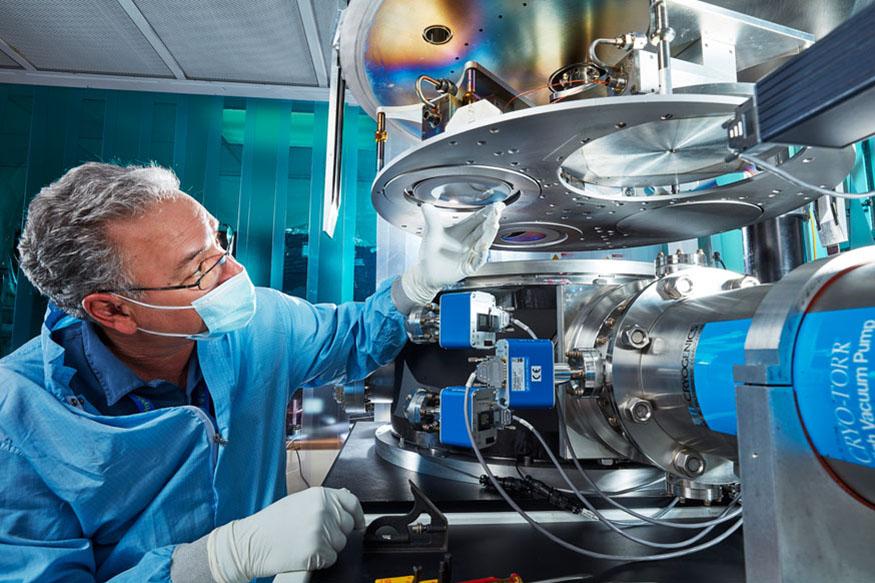

Jeff Robinson inspects a Si wafer substrate mounted in the Mag-1 deposition system.

Interior view of the Mag-1 system showing two sputtering sources (materials) used in thin film depositions. One source is 100-mm in diameter and the other is rectangular, 127x250 mm2 in size. Mag-1 can accommodate two sources of each size.

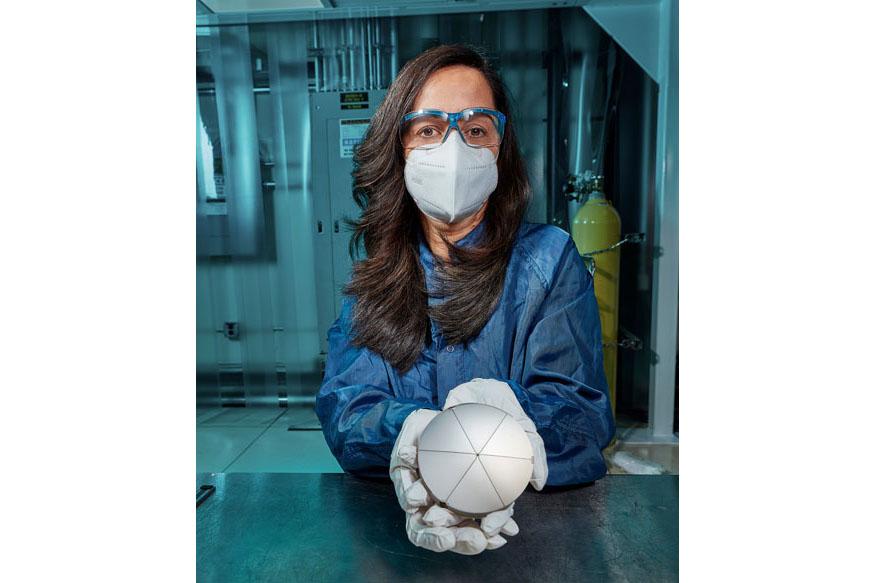

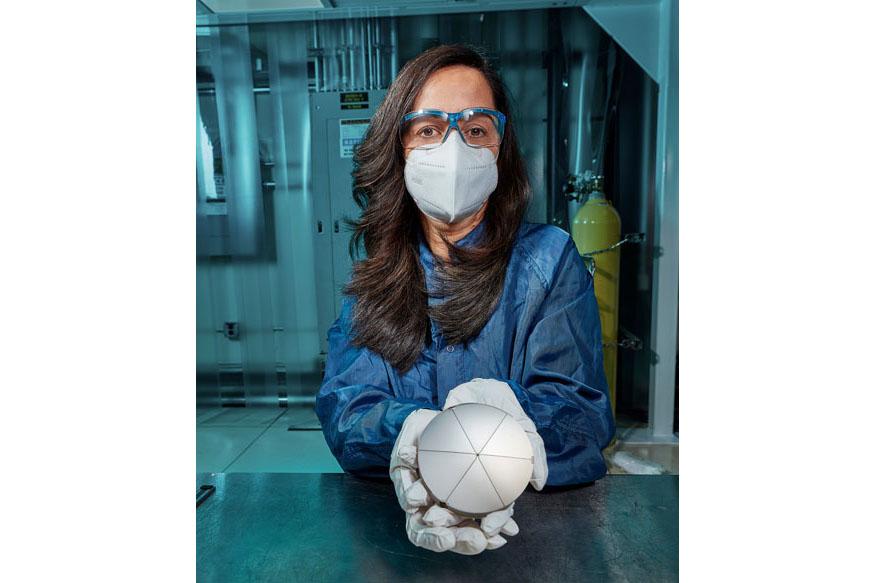

Jennifer Alameda holds a 150x150 mm2 superpolished, fused silica substrate coated with a periodic tungsten carbide/silicon carbide multilayer coating. The coating operates at grazing incidence angles in the hard x-ray/soft gamma-ray spectral range.

Jeff Robinson holds a 200-mm-diameter test primary mirror for the SUVI/GOES imager. Five (out of six) segments have been coated with molybdenum/silicon and molybdenum/yttrium multilayers. One segment has been left un-coated on this test mirror, revealing the fused silica substrate. The flight primary mirrors have all six segments coated, but otherwise are nearly identical to this test mirror.

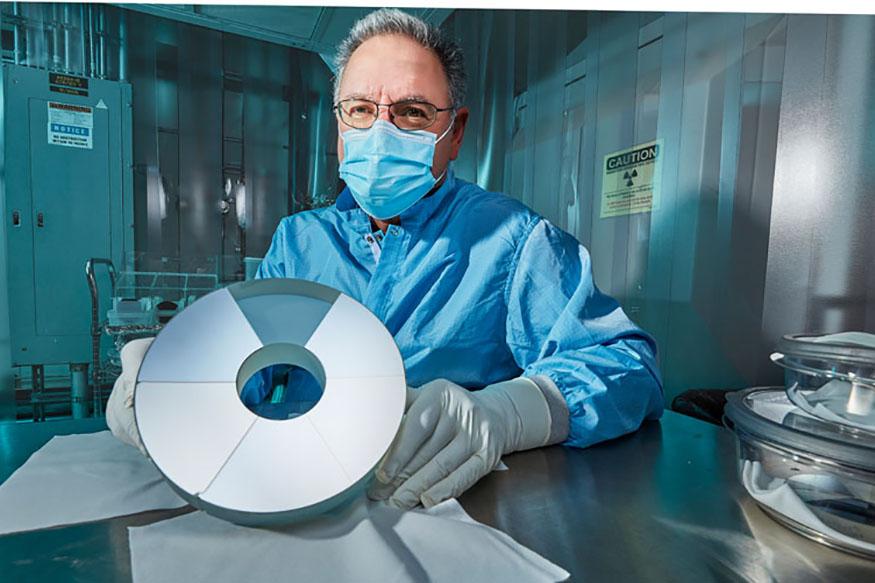

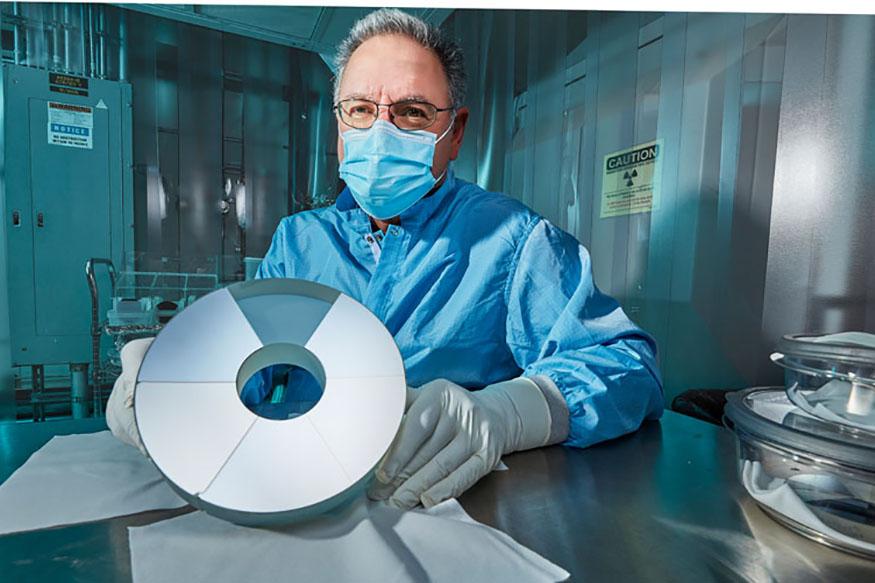

Regina Soufli holds a 92-mm-diameter test secondary mirror for the SUVI/GOES imager. This test mirror is nearly identical to the flight mirrors, with six segments each coated with molybdenum/silicon and molybdenum/yttrium multilayers to provide the six SUVI wavebands.

A close-up view of the test secondary mirror for SUVI/GOES. The overlap regions between coating segments appear as thin, dark lines. These regions were minimized in order to improve the performance of the SUVI instrument.

People

| Name | Title | Discipline |

|---|---|---|

| Team | ||

Collaborators

| Name | Department | Institution |

|---|---|---|

| Eric Gullikson | Center for X-ray Optics, PI for beamline 6.3.2 Advanced Light Source | Lawrence Berkeley National Laboratory |

| Farhad Salmassi | Center for X-ray Optics | Lawrence Berkeley National Laboratory |

| Patrick Naulleau | Center for X-ray Optics | Lawrence Berkeley National Laboratory |

| European Synchrotron Radiation Facility | ||

| Lockheed Martin Corporation | ||

| Advanced Photon Source | Argonne National Laboratory | |

| Franck Delmotte Group | Laboratoire Charles Fabry, Institut d’Optique Graduate School | University Paris-Saclay |

| Juan Larruquert Group | Instituto de Óptica | Consejo Superior de Investigaciones Científicas |

| Harvard-Smithsonian Center for Astrophysics | ||

| NASA Marshall Space Flight Center | ||

| Sandia National Laboratories | ||

| Idaho National Laboratories | ||

| Oak Ridge National Laboratory | ||

| Los Alamos National Laboratory | ||

| DTU-Space (Denmark) | ||

| Eberhard Spiller | Consultant | Lawrence Livermore National Laboratory |

| Yurii Platonov | Rigaku Corporation | |

| Reflective X-ray Optics, LLC | ||

| Phil Kaaret Group | University of Iowa | |

| Laboratory for Atmospheric and Space Physics | University of Colorado Boulder |

Select publications

The Emirates Mars Ultraviolet Spectrometer (EMUS) for the EMM Mission | Space Science Reviews, 2021

G.M. Holsclaw, J. Deighan, H. Almatroushi, M. Chaffin, J. Correira, J.S. Evans, M. Fillingim, A. Hoskins, S.K. Jain, R. Lillis, F. Hussain Lootah, J.B. McPhate, O.H.W. Siegmund, R. Soufli, and K. Tyagi

Optical, structural and aging properties of Al/Sc-based multilayers for the extreme ultraviolet | Thin Solid Films, 2021

J. Rebellato, R. Soufli, E. Meltchakov, E.M. Gullikson, S. de Rossi, C. Baumiere, F. Pallier, and F. Delmotte

High efficiency Al/Sc-based multilayer coatings in the EUV wavelength range above 40 nanometers | Opt. Lett., 2020

J. Rebellato, R. Soufli, E. Meltchakov, E. Gullikson, S. de Rossi, and F. Delmotte

Depth-graded Mo/Si multilayer coatings for hard x-rays | Opt. Express, 2019

C. Burcklen, T. Pardini, J. Alameda, J. Robinson, Y. Platonov, C. Walton, and R. Soufli

Lifetime stability and microstructure properties of Cr/B4C x-ray reflective multilayer coatings | Journal of Nanoscience and Nanotechnology, 2019

C. Burcklen, R. Soufli, J. Rebellato, C. Walton, E. Meltchakov, J.E. Rault, E. Gullikson, and F. Delmotte

Optical constants of magnetron sputtered Pt thin films with improved accuracy in the N- and O- electronic shell absorption regions | J. Appl. Phys., 2019

R. Soufli, F. Delmotte, J. Meyer-Ilse, F. Salmassi, N. Brejnholt, S. Massahi, D. Girou, F. Christensen, and E.M. Gullikson

Soft x-ray optical constants of sputtered chromium thin films with improved accuracy in the L and M absorption edge regions | J. Appl. Phys., 2018

F. Delmotte, J. Meyer-Ilse, F. Salmassi, R. Soufli, C. Burcklen, J. Rebellato, A. Jérome, I. Vickridge, E. Briand, and E. Gullikson

Aperiodic Mo/Si multilayers for hard x-rays | Optics Express, 2016

T. Pardini, J. Alameda, Y. Platonov, J. Robinson, R. Soufli, E. Spiller, C. Walton, and S.P. Hau-Riege

Cr/B4C multilayer mirrors: study of interfaces and x-ray reflectivity | J. App. Phys., 2016

C. Burcklen, R. Soufli, D. Dennetiere, F. Polack, B. Capitanio, E. Gullikson, E. Meltchakov, M. Thomasset, A. Jerome, S. de Rossi, and F. Delmotte

Demonstration of multilayer reflective optics at photon energies above 0.6 MeV | Optics Express, 2014

N.F. Brejnholt, R. Soufli, M.-A. Descalle, M. Fernández-Perea, F.E. Christensen, A.C. Jakobsen, V. Honkimäki, and M.J. Pivovaroff

A soft X-ray beam-splitting multilayer optic for the NASA GEMS Bragg Reflection Polarimeter | Exp. Astron., 2013

R. Allured, M. Fernández-Perea, R. Soufli, J.B. Alameda, M.J. Pivovaroff, E.M. Gullikson, P. Kaaret

Corrosion-resistant multilayer structures with improved reflectivity, US Patent 8,416, 829, 2013

R. Soufli, M. Fernández-Perea, and J.C. Robinson

Multisegmented, multilayer-coated mirrors for the Solar Ultraviolet Imager | Opt. Eng., 2013

D.S. Martínez-Galarce, R. Soufli, D.L. Windt, M.E. Bruner, E.M. Gullikson, S. Khatri, E.A. Spiller, J.C. Robinson, S.L. Baker, and E. Prast

Physics of reflective optics for the soft gamma-ray photon energy range | Phys. Rev. Lett., 2013

M. Fernández-Perea, M.-A. Descalle, R. Soufli, K.P. Ziock, J. Alameda, S.L. Baker, T.J. McCarville, V. Honkimäki, E. Ziegler, A.C. Jakobsen, F.E. Christensen, and M.J. Pivovaroff

Initial Calibration of the Atmospheric Imaging Assembly (AIA) on the Solar Dynamics Observatory (SDO) | Solar Physics, 2012

P. Boerner, C. Edwards, J. Lemen, A. Rausch, C. Schrijver, R. Shine, L. Shing, R. Stern, T. Tarbell, A. Title, C.J. Wolfson, R. Soufli, E. Spiller, E. Gullikson, D. McKenzie, D. Windt, L. Golub, W. Podgorski, P. Testa, and M. Weber

Spontaneously intermixed Al-Mg barriers enable corrosion-resistant Mg/SiC multilayer coatings | Appl. Phys. Lett., 2012

R. Soufli, M. Fernández-Perea, S.L. Baker, J.C. Robinson, J. Alameda, and C.C. Walton

Triple-wavelength, narrowband Mg/SiC multilayers with corrosion barriers and high peak reflectance in the 25-80 nm wavelength region | Opt. Express, 2012

M. Fernández-Perea, R. Soufli, J.C. Robinson, L. Rodríguez-De Marcos, J.A. Méndez, J.I. Larruquert, and E.M. Gullikson

The Atmospheric Imaging Assembly (AIA) on the Solar Dynamics Observatory (SDO) | Solar Physics, 2012

J.R. Lemen et al.

In-band and out-of-band reflectance calibrations of the EUV multilayer mirrors of the Atmospheric Imaging Assembly instrument aboard the Solar Dynamics Observatory | Proc. SPIE, 2012

R. Soufli, E. Spiller, D.L. Windt, J.C. Robinson, E.M. Gullikson, L. Rodriguez-de Marcos, M. Fernández-Perea, S.L. Baker, A.L. Aquila, F.J. Dollar, J. Antonio Méndez, J.I. Larruquert, L. Golub, and P. Boerner